Menu

- Home

- µ-Gasturbine

- Scavenger

- Project partners

- Contact

- Protected pages

Vibration scavenger

1. Introduction

The drive for miniaturization of electronic systems has lead to a research boost in miniature power generators. One class of these generators consists of devices that recycle energy available in the ambient. They are referred to as scavengers. Typical ambient energy sources are heat or mechanical vibrations. Scavengers can make use of different physical principles to generate electrical power from heat (thermoelectric effect) or from mechanical vibrations (e.g. electromagnetic, electrostatic or piezoelectric principle). Compared to other power sources, like batteries or fuel cells, scavengers do not rely on solid or liquid energy storage. This characteristic makes them particularly suited as power sources in autonomous sensor networks. This ‘storage free’ operation is unfortunately paid in terms of a limited amount of generated power (tens - hundreds µW).

2. The vibration scavenger

The most common way of scavenging vibration energy is based on the use of resonant systems, composed of a mass and a spring, enclosed in a frame. When the frame is in contact with a vibration source, the mass-frame distance varies. This distance variation is used to implement a converter. The converter extracts mechanical energy from the system and transforms it into electrical energy. A damper is normally used to represent the effect of the conversion system.

Figure 1: Basic construction of a vibration scavenger.

The maximum power that can be extracted from the system is proportional to the mass m, to the maximal amplitude of the mass vibration inside the frame Zmax, to the acceleration, aext, and to the angular frequency ωext of the vibration. This maximum power is obtained for a specific value of the damping. The converter must then be designed in such a way that the required damping can be achieved.

3. The converter

The converter can be electromagnetic (based, e.g., on the relative motion of a mass and a coil), electrostatic (based on a variable capacitance) or piezoelectric (based on the deformation of a piezoelectric material). For each of them the equivalent damping depends on their constructive parameters and on the electrical properties of the load circuit. It is always possible to tune the load in such a way that the optimal damping is reached. In principle, then, any converter is capable of delivering the maximal power. Anyhow, if the converter is not properly designed, the values of the load for which optimum damping is reached can be inconvenient (too large or too small).

Designing an appropriate converter becomes more and more difficult when the systems become small (e.g. the number of turns in the coil of an electromagnetic converter can be limited, the value of the variable capacitor in an electrostatic converter can become too low). Limitations can be partly overcome by using micro fabrication technologies.

4. A micromachined, electret based, electrostatic scavenger

For an electrostatic scavenger, the optimal damping is proportional to the quantity RV2(dC/dx)2, where R is the load resistance, V is the polarization voltage and (dC/dx) the change of capacitance per unit displacement. In order to avoid large values of the load, it is convenient to have large polarization voltages and effective variable capacitors.

|

|

| Figure 2: Operation principle of an electret based vibration scavenger. | Figure 3: Stability of the charge retention in electrets. |

Electrets are ‘permanent polarization sources’. They are dielectric layers where some electrical charges are trapped. An example is a double layer of silicon oxide - silicon nitride on a silicon wafer. By corona discharge positive charges are trapped at the interface between the two layers, while negative mobile charges are displaced into the silicon wafer. If an electrode is placed in front of this structure, a part of the mobile charges will be transferred to it. If the front electrode vibrates, an ac current flows in the load and vibration energy is transformed into electrical power.

Vibration scavengers based on electret do not need batteries for operation. Polarization voltages obtained by electrets are larger than typical battery voltage; the value of the load for maximal power is lower. Electrets are stable in time, especially if charged at potential below 150 V.

|

|

| Figure 4: Schematic of an electrostatic vibration scavenger. | Figure 5: View of the device from the glass wafer. |

A capacitor with large dC/dx is fabricated by micromachining. Two rows of fingers, on two different wafers, slide one against the other. The moveable fingers are patterned on the seismic mass. The electret wafer is used also to complete the hermetic packaging of the device.

5. A micromachined piezoelectric scavenger

A simple piezoelectric scavenger is formed by a cantilever beam coated with a piezoelectric layer and loaded with a mass. Fabrication technology can be similar to the one of the electrostatic scavenger in terms of packaging and bonding.

|

|

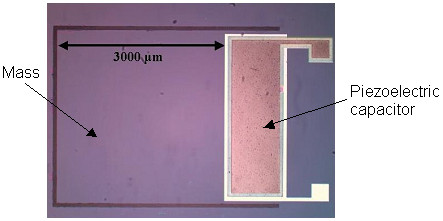

| Figure 6: Schematic of the piezoelectric scavenger. | Figure 7: Top view of the central wafer of the piezoelectric scavenger. |

Key factors for good performances is the use of a piezoelectric material with large piezoelectric constant and low dielectric loss. A good choice could be PZT (lead zirconate titanate). AlN, thus having inferior piezoelectric properties, can also be used. It has the advantage of being compatible with standard IC technologies.

Reply on content: Paolo.Fiorini at imec.be

Copyright © IMEC 2005